Class Certification + Crane Slip Ring Technology: Dual Safeguards for Next-Gen Ship Handling Safety

Global Certification + Core Component Upgrade: Mitigating Lifting Risks, Capturing Market Leadership

Why Marine Crane Slip Rings Require Class Certification:

✅ Safety Hazard Prevention

Slip ring contact failure → Crane control loss → Cargo drop!

CCS certification ensures electrical transmission stability, eliminating failure risks.

✅ Regulatory Compliance

IMO regulations mandate certified equipment. Non-certified cranes face port rejections and order loss.

✅ Maintenance Cost Reduction

Substandard slip rings shorten lifespan → Frequent downtime. Certified products extend service life by 50%, saving millions in maintenance.

✅ Technical Credibility

Class surveyors conduct full-scope audits (design to production), building owner trust.

Our Advantages

Core Slip Ring Technology:

•Precious metal contacts + multi-layer sealing

•Salt spray resistance, vibration proof, high-humidity operation

•≥99% current transmission efficiency, zero signal delay

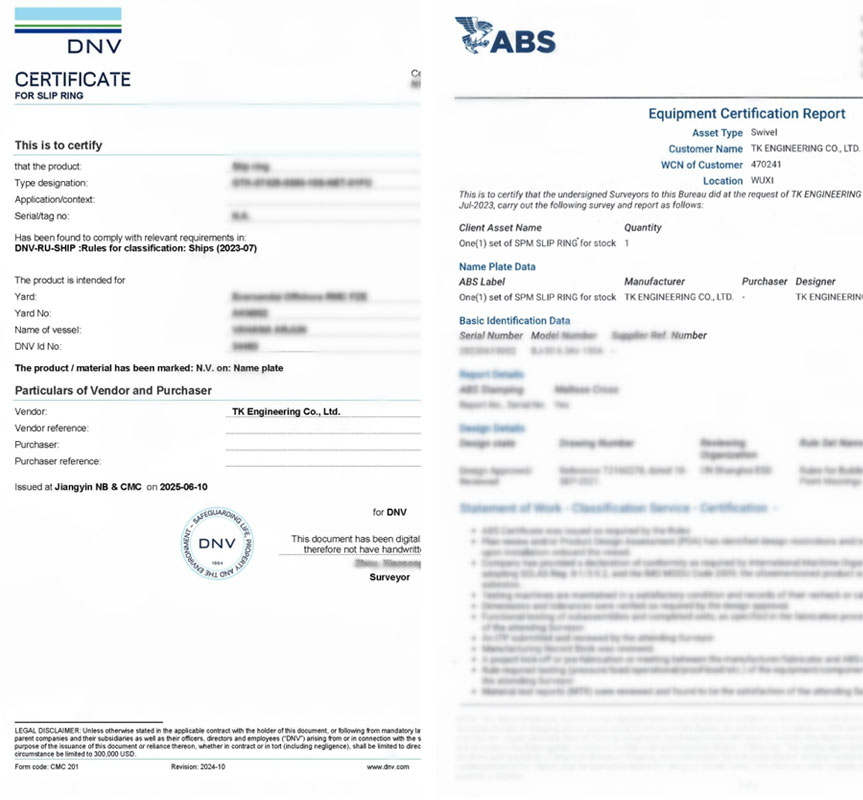

Class Certification Services:

•Partnerships with ABS, DNV, etc.

•Pre-audit simulations & tailored solutions (100% pass rate)

Certification Process

1️⃣ Requirement Assessment

1-on-1 expert consultation for customized certification planning

2️⃣ Technical Enhancement

Optimize sealing/conductivity to meet IMO Tier III standards

3️⃣ Survey Coordination

On-site class surveyor audits focusing on endurance testing & electrical safety

Key Client Concerns

Q: Compatibility with various crane models?

→ Customizable designs for MacGregor, TTS, and other OEMs.

Q: Will certification delay delivery?

→ Expedited channels available.